ULTRASONIC 80 eVo linear

Universal ULTRASONIC Machining Centre

Max. X-axis stroke

31 in.

800 mm

Max. Y-axis stroke

26 in.

650 mm

Max. Z-axis stroke

22 in.

550 mm

Max. workpiece diameter

31 in.

800 mm

Max. workpiece height

24 in.

600 mm

Max. workpiece weight

1,323 lbs.

600 kg

Control & software alternatives

SIEMENS

Highlights

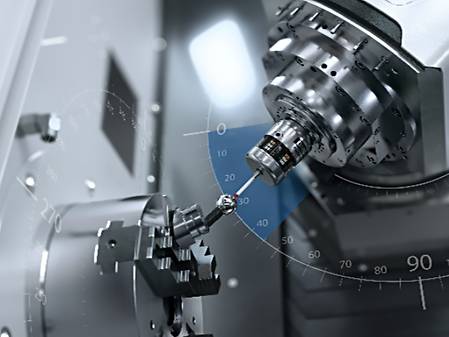

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 / HSK-A100 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

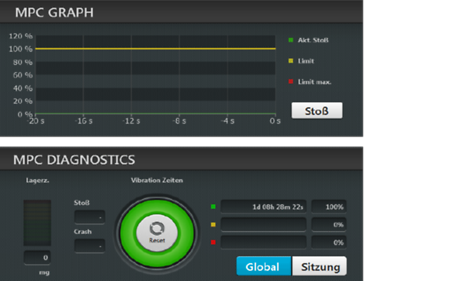

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

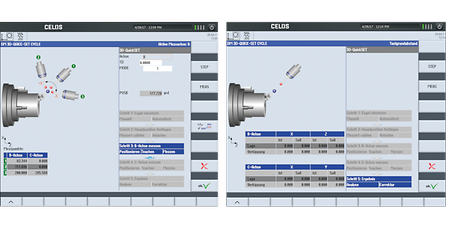

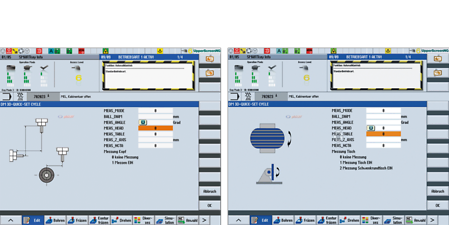

5-Axes Simultaneous Machining with proven Swivel Rotary Table

- Swivel range of the B-axis -5/ +110°

- Table load up to 600 kg

- Cooling of table unit table bearings and drives

Mill-Turn Operation

- Speed of the C-axis up to bis 1,200 rpm

- Motorspindle with 18,000 rpm, 130 Nm and HSK A63

Spindles

- speedMASTER 20,000 rpm in standard version

- speedMASTER 15,000 rpm with 200 Nm (option)

- Motorspindle 24,000 rpm (option)

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: