Machining Transformation (MX) by Process Integration, Automation, Digitization and Sustainability

Every 10 years, social needs change fundamentally. DMG MORI has always been evolving its business model to meet these needs with new products and services. Now, DMG MORI has matured into a provider of Machining Transformation (MX) to drive Green Transformation (GX) through process integration and automation of machine tools.

The three areas of Process Integration, Automation and Digital Transformation (DX) have an impact on Green Transformation. The social contribution consists of the resulting sustainability but also includes the solution to the shortage of skilled staff through automation as well as the development of top talent. This can be ensured through an extensive training program as part of digitalization. The goal is to focus on the qualifications of all types of employees – from engineer to machine operator.

Machining Transformation

Process Integration

5-axis opens opportunities in process integration

Workpieces that were sequentially processed by multiple machines can now be manufactured in one technology-integrated machine in a single set-up, such as a 5-axis machine or a mill-turn center to achieve higher accuracy. Following such complex technology integration, automation leads to further resource optimization, such as compensating for a lack of operators and elimination of intermediate work-in-process after each operation, which previously occupied shop floor space and costs. Digitization has helped optimize the machining process by visualizing and providing feedback from areas where operators cannot be involved due to automation.

Process Integration

High utilization of one machining center instead of partial utilization of several simple machines.

Technology Integration means that several processes such as turning, milling, grinding and measurement functions are combined in one machine tool for higher productivity. This integration reduces the number of operators needed, frees them from having to carry out multiple setups and contributes to a rewarding working environment within a company. More time can be devoted to high value-added operations, making work more rewarding for staff.

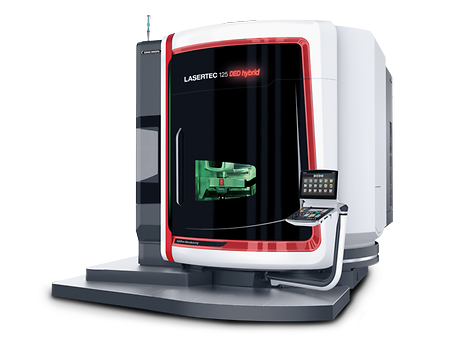

The integration of several technologies like Turn-Mill, Mill-Turn (FD), ULTRASONIC, LASERTEC and ADDITIVE MANUFACTURING (DED / DED hybrid) in a single machine tool ensures higher productivity, saves resources and reduces CO2 emissions.